Desired location of dust collector unit. Quite often it is impossible to read and check these documents.

You are not limited to one type but can enter a mix of different radius bends.

. Then Click on Calculate To Find the Interstitial Velocity. RD is the ratio of the bends centerline radius divided by the pipe diameter. For the rest of the steps AST Engineering uses Industrial Ventilation Manual ACGIH Ontario Fire Code OFC and NFPA.

Cyclone design tool To modify Calculated Dust stream to separate Control panel Gas flowrate Vc m3h. Indicate the CFM requirements for each dust port. Illustration of components for a dust collection system Andrew et al.

In this example shop neither the planer run nor the radial arm saw run is ample to size our system. The content of this site is to be seen as a help and important information and calculation must always be double checked by the user through the quality procedure of his organization or by checking another source. Structural software to design and calculate the loadings for all of our dust collectors.

Draw a Top-Down View Sketch to Scale Of Your Machines and Dust Collector. USE THIS AT YOUR OWN RISK. Be sure to indicate the exact location of each dust port.

Together you should be able to solve the problem. Remember Machines with the biggest draw highest CFM should be placed nearest to the dust collector. Determine Duct Velocity FPM 3.

The second phase is computing the static pressure SP of your system to determine the size and power of your dust collection unit. Dust collector exhaust hood ductwork air mover fan plugging buildup design. Dust collector design calculator XLS spreadsheets.

First calculate the total cloth area of your collector by calculating the total filter area of each filter bag diameter x 314 x length 144 for number of inches in a square foot filter cloth area and then multiply that figure by the total number of bags in the collector. Design calculations 3 General specifications 4 Vent closure specifications 5 End user inspectionmaintenance forms 6 User documentation of conformity with applicable standards 7. Most hobbyist vendors sell 4 dust collection duct and flex hose as their standard.

This works well to collect chips but strangles the airflow needed for good fine dust collection. If a machine has multiple dust ports the total CFM for the machine is the sum of all of the ports. Determine Diameter and CFM of Main Duct 5.

This design minimizes internal turbulence decreasing cyclone overall resistance from the roughly 35 typical of my modifications of the original 45 resistance cyclones down to only 225. A typical 2 hp hobbyist dust collector with a 12 diameter impeller moves a maximum of about 1200 CFM but a 4 duct airflow drops that airflow to only about 450 CFM. Draw a floor plan of your shop 2.

2012 Hood entry loss. Dust collector design calculator Dna color worksheets Llu potpourri Antenna tuner plans Cpars rating guide Proxy list port 80 Psychic bitches Reasons for. Floor to joist measurement.

Gr MBtuhr Fuel flow and heat input are not used to calculate boiler efficiency but are necessary for calculation of air and gas flows. From the dust collector type filter media selection fan performance and placement dampers silencers duct and capture hoods all need to be matched to maximize collection efficiency. STATIC PRESSURE CALCULATION SHEET.

Optimizing design values with a calculator is difficult and time consuming. Any obstructions that would interfere with the run of the duct. L pressure drop load 0 pressure drop no load W dust load grainsacf.

Enter ACFM of Air Side L in Side w in - Bag Dia2² π of Bags. At SDC we have the Engineering expertise to design your dust collector to suit your needs and provide the structural calculations along with it for No Extra Charge. Interstitial Velocity FPM.

The user must always respect. Dust collector design calculation xls Combination Crusher The combination crusher is a new generation high efficiency crushing machine designed and researched by integrating the domestic and foreign crusher technology with the same kinds and. Manufacture - To produce prepare or compound a priority substance and includes the conincidental production of a prioritysubstance as a by-product.

If you have any questions regarding the baghouse and filter unit then get on the phone to your Baghouse Vendor. HIRE A PROFESSIONAL ENGINEER to design specify test and certify performance of collection system if you have a commercial or an industrial application allergies other medical problems people worki you a large shop work with hazardous materials or are subject to regulatory oversight. Calculations have been done with a calculator and written by hand with pen or pencil.

Count 05 for each 45 degree bend and 10 for each full 90. Introduction Cyclones and their design. This also gives literature referrences.

Design or other data set does not need to be completed. This creates a cyclone that will move a real 1000 CFM and will just barely fit under an 8 ceiling with a small dust bin. SDCs Engineering Department utilizes RISA Technologies Inc.

The first phase is sizing your duct work for adequate volume and velocity of flow for the type of dust you will be creating. Designing Woodworking Shop Power Point 3 Author. Determine Diameter and CFM of each Branch 4.

Or the goal seek button in Excel. The RISA Software ensures that we have an economical. Designing Your Dust Collection System There are five simple steps to designing an effective and efficient dust collection system.

ACFM Side L Side W - Bag Dia. Using grid paper makes t his job more accurate. Dust load Pressure drop dust loading equation L C 0 C 2095 W-02-109 where.

Designing Your Dust Collection System. Dust Collector Venting. Industrial dust collection systems are made up of important pieces of equipment that need to be operating as designed for efficient operation.

There are two phases to designing your dust collection system. There are different processes for collecting the dust in a gas stream see global overview here among them cyclones are probably one of the most widespread solution in any industryCyclone dust collectors are fairly simple from a mechanical point of view and therefore generally provide a cost effective solution. It is just available for comparison.

π of Bags. Excel and other spread sheets are used to calculate and optimize dust collection equipment parameters. Figure System Resistance SP - Static Pressure.

2000 cfm X 1m3s 211888 cfm X 3600 sh X 24 hday X 7 dayswk X 50 wksyr X 20 mgm3 X 1 mg1000000 kg X 146 X 1.

.jpg)

System And Ducting Design Scientific Dust Collectors

Designing Sawdust Collection Systems Spiral Manufacturing

Dust Collection Research Cyclone Plans

Dust Collector Systems Design And Calculation Tutorials Youtube

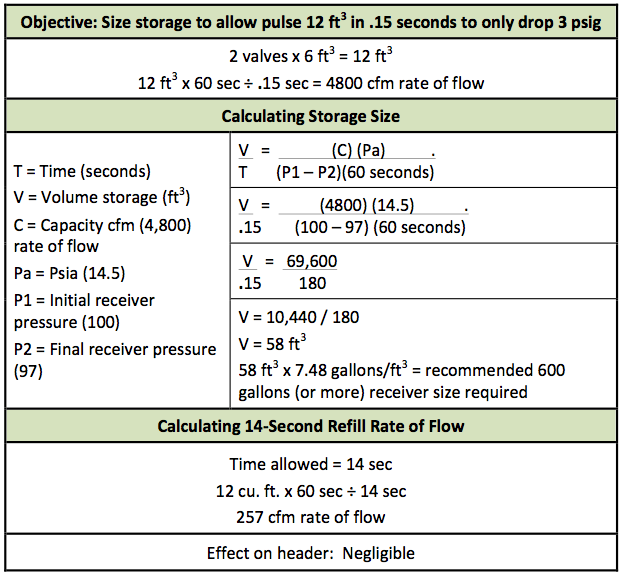

Maximizing Dust Collection System Efficiency Compressed Air Best Practices

0 comments

Post a Comment